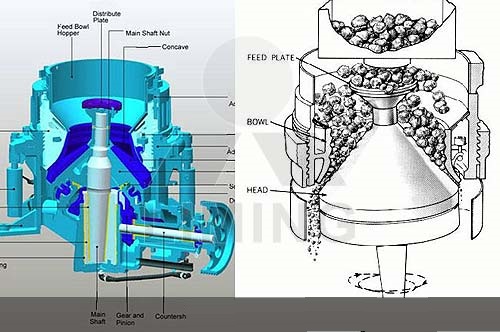

Cone Crusher breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper. Rocks get squeezed at the same moment when it enters in between the bowl liner and mantle. Only one time breaking is carryout of larger pieces of rocks from ore.

Broken pieces of rocks fall down to the next position where it is broken again. Same process continues until the broken pieces become small enough so that it can pass through the narrow opening that is at the bottom of the cone crusher.

Although the eccentric speeds of the various sizes of this type are not quite so high as the speeds used for the Newhouse crusher, the Hydro-cone crusher definitely rates as a high-speed machine, its product comparing quite closely to that of the former type, for equal close-side settings. Probably the outstanding feature of the. Hydrocone crusher is the hydraulic support, from which its name is derived and which is clearly shown in the sectional view. This device makes it possible to adjust the crusher to any desired setting within its range in a matter of seconds, adjustments may be made while the crusher is running, although the feed must be shut off before operating the adjusting pump. An accumulator in the hydraulic system provides protection against tramp iron or packing.